Gas-liquid filter |

|

|

|

Product name:Gas-liquid filter |

|

Item:GMWM-17 |

|

Details: |

|

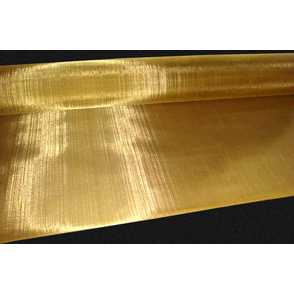

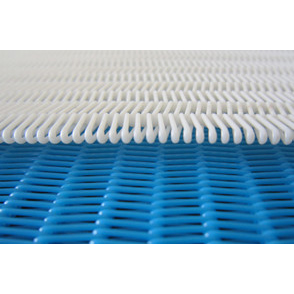

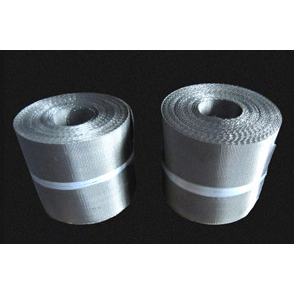

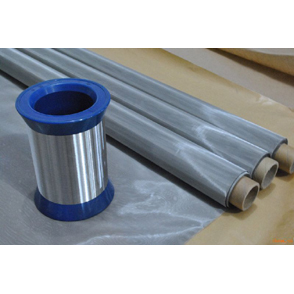

Gas-liquid filter Gas-liquid filter uses and structures:Also known as vapor-liquid gas-liquid filter mesh, broken foam network, (referred to as gas-liquid network, also called mist nets, woven wire mesh, knitted net, braiding wire, shielding wire mesh,), is a kind of a special the form of woven wire mesh for the chemical industry in the production of wire mesh demister, wire mesh demister, catalyst and distillation, evaporation, absorption process in the droplet entrainment in the gas and liquid foam to eliminate or capture; machinery and equipment used in manufacturing processes in the oil and gas separation, oil and water separation, gas-liquid separation, shock absorption silencers, sealing components, etc.; for environmental protection in the field of dust, in addition to water, fogging, air purification, flue gas desulphurization, water treatment equipment, oil-water separators; various occasions, the separation, filtration devices; cars, tractors filter; auto parts in the sealing, shock absorption (shock), silencers and exhaust cleaning components; electronics, electrical appliances electromagnetic interference shielding devices are widely used. Gas-liquid filter products in China's most widely used occasion: petroleum, petrochemical, chemical, light industry, medicine, metallurgy, aerospace, shipbuilding, automobile, machinery, muffler shock absorption, pressure vessels, drying tower, absorption tower, desulfurization tower, In addition to the environmental projects of water fog removing dust; used for filtration, screening, catalyst and distillation, evaporation, absorption process in the gas-liquid separation, gas and water separation. Wire diameter size range: |

|

|

←[Previous:GMWM-16] [Next:GMWM-18]→ |

| Related Products : |

Home | About Us | Products | FAQ | Feedback | Contact Us | SiteMap

Copyright (c) SAILIN WIRE MESH , WIRE MESH MACHINE , FILTER MACHINE All Rights Reserved Partner